Water Treatment

I-beam supports (see Tank Accessories) are available to help you comply with SPCC inspection requirements. With almost ninety years of history, the galvanized steel tanks are G-90 grade 20 gauge metal made in the USA. After the tank is constructed, a paint / epoxy lining is applied to the inside of the tank to supply a protecting barrier between the water and the steel itself. This product is FDA accredited for potable (drinking) water functions and is ANSI / NSF 61 certified. Each tank is tested on the manufacturing unit to ensure that it is watertight.

Corrugated Steel Water Tanks

We value creating sustainable products and whereas time will finally catch up to each tank, the metallic is 100 percent recyclable. G145 galvanized tank shellNSF/ANSI sixty one licensed linerGeomat liner protection layer2" outlet & drain with metallic ball valves20" inlet basket with light guardplus rather more... Our tanks are additionally accredited and included in building plans for cities, counties, college districts, and municipalities. Let us know the information you want for the project plans you may be working on.

This kind of bathroom float is relatively new and barely improved than the float cup. The main benefit of placing in one is that it refills slowly and has a more exact water shut-off. In selecting the best rest room fill valves, we extensively researched dozens of fashions and appeared for ones that came with high customer satisfaction both in quality and in ease of installation. Some of today’s bathroom fill valves work on the identical basic float system, but they comprise a small internal float situated contained in the valve stem. While you won’t see an inner float rising and falling with the water level, it'll still open and shut the water inlet as wanted. These valves are most frequently seen in older techniques, reservatorios metalicos de agua but there may be different causes for selecting this kind of fill valve, such as needing an adjustable toilet fill valve.

This kind of bathroom float is relatively new and barely improved than the float cup. The main benefit of placing in one is that it refills slowly and has a more exact water shut-off. In selecting the best rest room fill valves, we extensively researched dozens of fashions and appeared for ones that came with high customer satisfaction both in quality and in ease of installation. Some of today’s bathroom fill valves work on the identical basic float system, but they comprise a small internal float situated contained in the valve stem. While you won’t see an inner float rising and falling with the water level, it'll still open and shut the water inlet as wanted. These valves are most frequently seen in older techniques, reservatorios metalicos de agua but there may be different causes for selecting this kind of fill valve, such as needing an adjustable toilet fill valve.Pressure-Assisted Fill Valve

Following are particulars of the categories including a review of the most effective fill valves. The constructor inspection check plan (ITP) must also include witness points during construction. External insulation ought to be covered with a continuous flat aluminium vapour barrier. Single profiled sheets for the aluminium vapour barrier should not be used.

Clean the tanks as recommended by the manufacturer, typically each 5 years, to stop sediment buildup and preserve water quality. Fiberglass and concrete tanks are probably to have long lifespans but could be tougher to repair if broken. Plastic tanks, whereas simpler to handle and set up, may degrade sooner with exposure to UV mild. Steel tanks, however, require regular upkeep to forestall rust, significantly in humid environments. For properties with wells that battle to keep up with water demand, including a number of storage tanks could be a cost-effective solution compared to drilling a deeper well.

Adjust a brass diaphragm ballcock rest room fill valve by bending the steel float rod up or down to manage the level of the water in the tank. While this can normally be completed before the tank refills, turn off the water provide valve at the bathroom base when you need extra time. Integrating a rainwater harvesting system along with your storage tanks can present an extra, sustainable water source. Collected rainwater can be used for irrigation, flushing bogs, or even handled for potable use, relying in your set up and native regulations. This setup can further scale back dependence on a low-yielding well and improve overall water provide resilience.

Additional Water Storage Tanks for Low-Yielding Wells

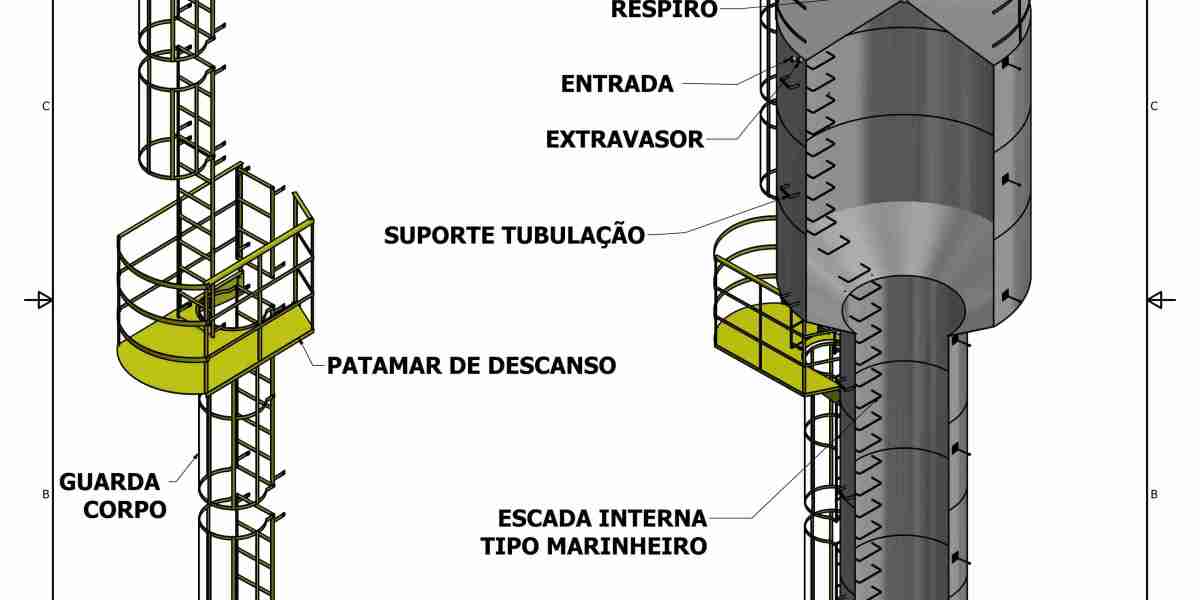

The silent fill offers a gracious expertise by filling the tank quietly. It comes with a universal design that adjusts easily from 10 – 15 inches and is good to be used in high effectivity 1.28 to 1.6 gallons per flush bathrooms. This is a newer variation of the float cup kind with a hid internal and smaller float lever inside the head of the valve. Compared to the exterior float cups, inside floats have a condensed design and have a exact shut-off. The stairway to the top of the tank should be a spiral type, with a separate standalone entry tower.

The Best Toilet Repair Kits, Vetted